SUCCSESS IN METAL FORMING

Through targeted and cost-effective product developments

Expert support in product development and design

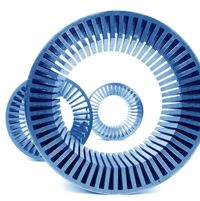

Stator & rotor sheets: Precision and flexibility for a wide range of industrial applications

Our stator and rotor sheets are used in electric motors and generators, which are employed in key industrial sectors. These include, among others, the energy industry, the transportation sector, mechanical and plant engineering, the railway industry, and the electrical industry. We place great emphasis on meeting the individual requirements of our customers while ensuring the highest precision and efficiency in manufacturing.

Innovative manufacturing processes for every

requirement

The production of our sheets is carried out using state-of-the-art technologies, offering maximum flexibility for various requirements:

- Progressive stamping: Ideal for small diameters ranging from 10 mm to 400 mm, this process enables high productivity with consistent precision.

- Single punching and trimming: This process is ideal for larger diameters ranging from 400 mm to 850 mm and guarantees precise results for complex geometries.

- Laser cutting: Specifically for small series and prototypes, this process is highly flexible and allows for precise processing even with challenging designs.

- Serration, where the sheets are mechanically connected

- Riveting, for a robust and stable connection

- Welding, ensuring a particularly durable attachmen

Custom packaging solutions for your requirements

The packaging of sheets and stacks plays a crucial role in transport and further processing. Depending on your requirements and the specific further processing, we develop tailor-made packaging solutions that optimally protect your products and ensure smooth logistics.

Comprehensive consultation by our experts

To ensure that your individual requirements and needs are fully considered, our experienced team of experts is here to provide guidance. Together, we analyze your needs and find the ideal solution for your project – from production to assembly and packaging.

Our sheets are made from high-quality steel with a thickness of 0.3 to 1 mm, using both steel and carbide tools. In our in-house tool manufacturing, we carry out all tool refurbishments and maintenance in the shortest possible time. Depending on the product requirements, we can design multi-row tools to ensure production with the highest efficiency and at highly competitive prices.

This approach combines material quality, precision, and flexibility to meet demanding customer requirements. The use of high-quality steel ensures durable, resilient laminations that can be used in various applications such as electric motors or generators. The in-house tool manufacturing guarantees a quick response to maintenance requests, minimizing production interruptions. Additionally, the ability to develop specially customized multi-row tools offers significant advantages: higher production speed, reduced material usage, and optimized cost structures. This combination makes the production process efficient and cost-effective – an ideal solution for customers who value both quality and cost-consciousness.

Variety and expertise in stamping and forming technology

Rely on us as your competent partner in stamping and forming technology – for various industries and individual requirements.

Range of services

Manufacturing processes

Wide range of services

We offer cost-effective and assembly-ready components tailored specifically to your requirements. Our core competencies lie in fine cutting, stamping, and forming. Depending on the degree of forming, material properties, and production volume, we select the optimal manufacturing process to ensure the highest efficiency and quality. This choice is supported by thorough cost-effectiveness analyses and calculations.

Tool

Multi-stage tool solutions

We offer the development and manufacturing of multi-stage tools that combine several process steps – such as cutting, forming, and deburring – in a single operation. This technology allows for the efficient and direct production of complex and demanding components within the tool itself. The fewer subsequent operations required, the more cost-effective and faster the manufacturing process becomes. Our innovative methods enable us to integrate burr formation directly into the tool, ensuring parts are both precisely cut and deburred – all in a single operation.

Simulation und prototyping

Systematic Testing

Through simulation-based feasibility studies, we accelerate the process of designing parts that are suitable for fine cutting and forming, as well as material-optimized. This is a crucial prerequisite for minimizing production costs. Our experts simulate your ideas, continuously optimize them, and achieve the best results for tools and components. With prototypes, we check for potential weaknesses and test the parts under real conditions. Our prototyping approach enables efficient and cost-effective perfection of the design and function of the components – an ideal foundation for a quick and smooth start to serial production.

Toolmaking

Tailored solutions

Toolmaking is the key to achieving the highest precision, reliability, and competitiveness. It is the foundation for every function-critical component and significantly influences the quality of the final product. Tecsta relies on a strong network and stands out through close collaboration with our partners, Özteknik and Pars Kalip. Together, we develop and manufacture the tools 100% in Turkey.

Engineering

Optimal Synergy

An efficient manufacturing process is created through the close integration of component design, tool development, and manufacturing concept. We offer holistic solutions that cover all aspects: from the design of the tools to risk analysis and the planning of the entire manufacturing process. This comprehensive approach allows us to develop economical and effective production concepts.

Qualitäty management

Reliable quality from start to finish

Our quality management begins during the development and quotation phase and accompanies every project until production start. We place great emphasis on careful monitoring and documentation of all work steps during serial production. This ensures that all requirements and specifications are met at all times.

With continuous optimization processes, we not only secure quality but also constantly improve the efficiency of our manufacturing. Through this systematic approach, we guarantee that our customers always receive a product of the highest precision and reliability.

Product examples